Insider Brief

- Scientists at the University of Warwick and the National Research Council of Canada have demonstrated the highest hole mobility ever recorded in a silicon-compatible material.

- The team achieved this by engineering a nanometre-thin, compressively strained germanium layer on silicon that enables electrical charge to move with unprecedented efficiency.

- The material’s performance points to faster, lower-power chips with applications in quantum information processing, AI hardware, and advanced semiconductor devices.

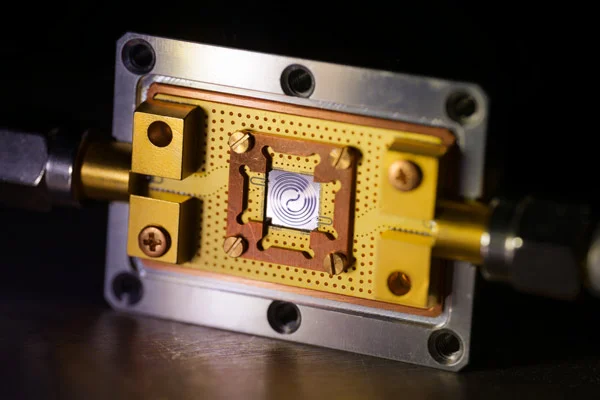

- Artistic Sketch of the fastest charge carrier ever on a silicon wafer. (Maksym Myronov / University of Warwick)

PRESS RELEASE — Scientists at the University of Warwick and the National Research Council of Canada have achieved and measured the highest “hole mobility” ever recorded in a silicon-compatible material.

Most modern semiconductors are fabricated of or on Silicon (Si), but as devices get smaller and denser, they dissipate more power and as a result, are reaching their physical limits. Germanium (Ge)— once used in the first transistors of the 1950s — is now making a comeback as researchers find new ways to harness its superior properties while keeping the benefits of silicon’s established manufacturing technologies.

In a new study, published in Materials Today, a team led by Warwick’s Dr Maksym Myronov achieved a major step towards the next generation of electronics — creating a material using a nanometre-thin, compressively strained germanium epilayer on silicon, that allows electrical charge to move faster than ever before in a material compatible with modern chipmaking.

Maksym Myronov, Associate Professor and leader of the Semiconductors Research Group, Department of Physics, University of Warwick says “Traditional high-mobility semiconductors such as gallium arsenide (GaAs) are very expensive and impossible to integrate with mainstream silicon manufacturing. Our new compressively strained germanium-on-silicon (cs-GoS) quantum material combines world-leading mobility with industrial scalability — a key step toward practical quantum and classical large-scale integrated circuits.”

The breakthrough was achieved by carefully engineering a thin germanium layer on top of a silicon wafer. By applying just the right amount of strain to the germanium layer, they created an ultra-clean crystal structure that allows electrical charge to flow almost without resistance.

When evaluated, the material demonstrated a record hole mobility of 7.15 million cm² per volt-second (compared to *** in industrial silicon), meaning charge can move through it far more easily than in silicon. This could enable future chips to run faster and dissipate less energy.

Dr Sergei Studenikin, Principal Research Officer, National Research Council of Canada adds: “This sets a new benchmark for charge transport in group-IV semiconductors – the materials at the heart of the global electronics industry. It opens the door to faster, more energy-efficient electronics and quantum devices that are fully compatible with existing silicon technology.”

The research establishes a new pathway for ultra-fast, low-power electronics, with potential applications spanning quantum information processing, spin qubits, cryogenic controllers for quantum processors, AI, and data-centre hardware with reduced energy and cooling demands.

This advance also marks a major milestone for Warwick’s Semiconductors Research Group, reinforcing the UK’s leadership in semiconductor materials science.