- Toyota Systems and Fujitsu, in collaboration with Toyota Motor Corporation, applied quantum-inspired optimization and AI to automate connector pin placement in automotive ECUs.

- The approach reduced design computation time by more than 20× by replacing manual, expertise-driven review of extremely large design combinations.

- The technology has been used in Toyota’s mass-produced ECUs since May 2025, with plans to expand adoption across suppliers and manufacturing processes.

PRESS RELEASE — Toyota Systems Corporation (Toyota Systems) and Fujitsu Limited, in collaboration with Toyota Motor Corporation (Toyota), today announced the successful application of quantum-inspired technology and AI to automate one aspect of the automotive parts design process.

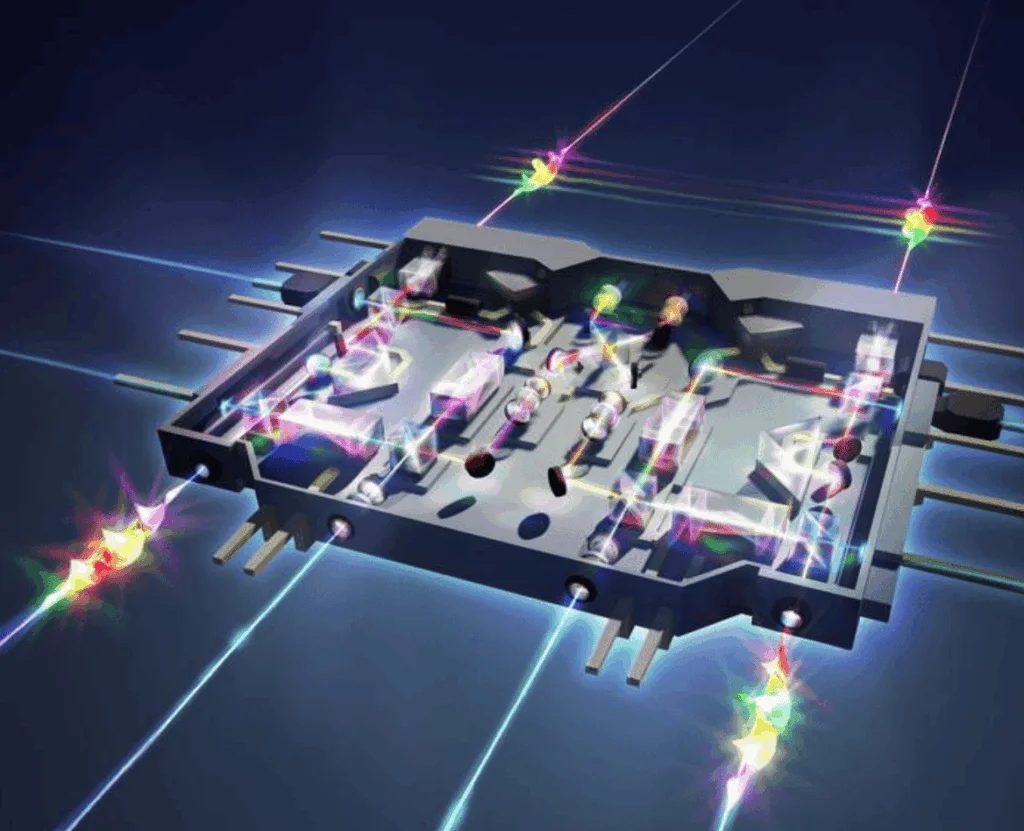

In a world first for the automotive industry, the technology was applied to automate the placement design for connector pins, metal parts that enable the transmission of electrical signals across circuits and components. The parts are deployed in the car’s electric control unit (ECU), a small onboard computer that controls the vehicle’s systems.

The mobility industry faces demand for sustainable product development and the need to address increasingly complex software and hardware designs but is facing a severe shortage of skilled personnel. In the ECU development process at Toyota, the connector pin placement design for a 100-pin terminal array theoretically involves a vast number of combinations (9.3 x 10^157). This led to prolonged design review times and reliance on individual expertise.

To address these issues, Toyota Systems and Fujitsu, in collaboration with Toyota, tried to automate the process applying Toyota’s design standards and expertise, Toyota Systems’ operational and infrastructure knowledge in Computer Aided Engineering (CAE) analysis [1] for the Toyota Group, and Fujitsu’s Digital Annealer, a core component of Fujitsu Computing as a Service, and its AI technology.

This initiative involved training an AI model with information on connector pin placement patterns and their evaluation scores, previously determined by the knowledge and experiences of skilled engineers. This AI model was then converted into mathematical expressions and processed at high speed by the Digital Annealer to automatically calculate the optimal connector pin placement. As a result, the process was accelerated by more than 20x compared to conventional methods.

Both companies began applying this mechanism in actual operations for Toyota’s mass-produced ECUs in parallel with conventional methods starting in May 2025.

Moving forward, Toyota Systems aims to expand this development to supplier companies, promoting the application of cutting-edge technology and digitalization in Toyota Group’s wider manufacturing processes. Fujitsu will contribute to realizing a safe, secure, and comfortable mobility society by supporting the Toyota Group’s sustainable development and design. Both companies will work to improve development speed and quality and reduce costs by expanding the application scope of this mechanism.