Insider Brief

- Rice University researchers have developed a new technique to produce ultrathin, high-purity diamond films for advanced technologies by eliminating the need for high-temperature annealing in the lift-off process.

- Instead of heating, the method uses diamond overgrowth to convert a buried damage layer into a graphite-like seam, allowing clean separation of the diamond layer while preserving the substrate for reuse.

- The resulting diamond films are electronic-grade quality and could accelerate the development of next-generation quantum sensors, electronics, and thermal management systems.

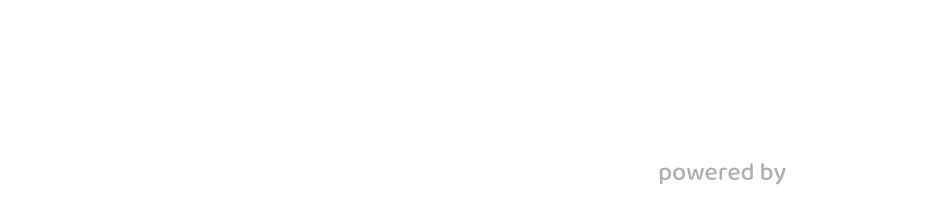

PRESS RELEASE — Diamond is one of the most prized materials in advanced technologies due to its unmatched hardness, ability to conduct heat and capacity to host quantum-friendly defects. The same qualities that make diamond useful also make it difficult to process. Engineers and researchers who work with diamond for quantum sensors, power electronics or thermal management technologies need it in ultrathin, ultrasmooth layers. But traditional techniques, like laser cutting and polishing, often damage the material or create surface defects.

Ion implantation and lift-off is a way to separate a thin layer of diamond from a larger crystal by bombarding a diamond substrate with high-energy carbon ions, which penetrate to a specific depth below the surface. The process creates a buried layer in the diamond substrate where the crystalline lattice has been disrupted. That damaged layer effectively acts like a seam: Through high-temperature annealing, it turns into smooth graphite, allowing for the diamond layer above it to be lifted off in one uniform, ultrathin wafer.

A team of researchers at Rice University has developed a simpler and more effective way to achieve lift-off: Instead of high-temperature annealing, they discovered that growing an extra epilayer of diamond atop the substrate after ion implantation is enough to turn the damaged layer graphite-like.

According to a study published in Advanced Functional Materials, the refined technique can bypass the high-temperature annealing and generates higher-purity diamond films than the original substrates. Moreover, the substrate sustains minimal damage in the process and can be reused, making the whole process resource-efficient and scalable.

“We found that diamond overgrowth converts the buried damage layer into a thin graphitic sheet, removing the need for energy‑heavy annealing,” said Xiang Zhang, assistant research professor of materials science and nanoengineering at Rice and a corresponding author on the study. “The resulting diamond film is purer and higher-quality than the original diamond, matching the electronic-grade quality.”

According to Zhang, these ultrapure diamond films “could revolutionize electronics, enabling faster, more efficient devices, or serve as the foundation for quantum computers that solve problems beyond today’s reach.”

To grow a new layer of diamond on the substrate, the researchers used microwave plasma chemical vapor deposition, a method that deposits new diamond material onto the surface in perfect alignment with the underlying crystal. The researchers hypothesized that the conditions of the growth process itself were enough to drive the conversion of the buried damage layer into graphite, without the need for additional heating.

To confirm this theory, the team examined how the interfaces between the diamond substrate, the buried damage layer and the overgrown film evolved during diamond overgrowth using a combination of transmission electron microscopy, electron energy loss spectroscopy, Raman spectroscopy and photoluminescence mapping.

“By correlating atomic‑level imaging with spectroscopic signatures, we demonstrate that diamond overgrowth is sufficient to form a clean graphitic release layer, preserve substrate smoothness and yield electronic‑grade diamond films, which is crucial for quantum technologies,” Zhang said.

By simplifying production and boosting sustainability, the new method could enable the development of transformative diamond-based technologies. The finding represents one of the major achievements attained through a long-standing collaboration between Rice and the United States Army Research Laboratory.

The research was supported by the U.S. Army Research Office under Cooperative Agreement Number W911NF-19-2-0269, the National Science Foundation (2032567, 2326628), the Air Force Office of Scientific Research (FA2386-21-1-4084), the W. M. Keck Foundation, the Sloan Research Fellowship, the Brazilian agency São Paulo Research Foundation (2023/08122-0), National Council for Scientific and Technological Development–Brazil (304957/2023-2) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior–Brasil. The content herein is solely the responsibility of the authors and does not necessarily represent the official views of the funding organizations and institutions.