Insider Brief

- John Martinis writes in the FT that quantum computing progress now depends on industrial-scale manufacturing rather than new scientific demonstrations.

- He argues that reaching a million-qubit system requires integrated cryogenic chips and abandoning outdated methods like the lift-off process that limit scalability.

- Martinis says shifting to advanced fabrication is both a technical necessity and an economic opportunity to rebuild U.S. manufacturing and broaden the benefits of quantum technology.

Quantum computing’s next breakthroughs will come from factories, not physics labs, according to John Martinis, who wrote in the Financial Times (FT) that the field is hitting a wall that only advanced manufacturing can fix.

Martinis, a professor at the University of California, Santa Barbara, co-founder of Qolab and 2025 Nobel Prize winner, writes in FT that recent scientific gains — including Google’s test to define the limits of a “quantum observable” — show the theory holds up.

But the machines themselves are stuck. He argued that a general-purpose quantum computer will require at least a million physical qubits, a number that is far beyond today’s devices and out of reach without a fundamental shift in how the hardware is built.

Over the past six years, Google’s quantum chips only doubled in size from 53 to 105 qubits, Martinis writes in the FT, a pace he warned will leave the field decades away from practical systems. The slow growth stems from a basic problem: the physical complexity of modern systems.

Tangled up in Q

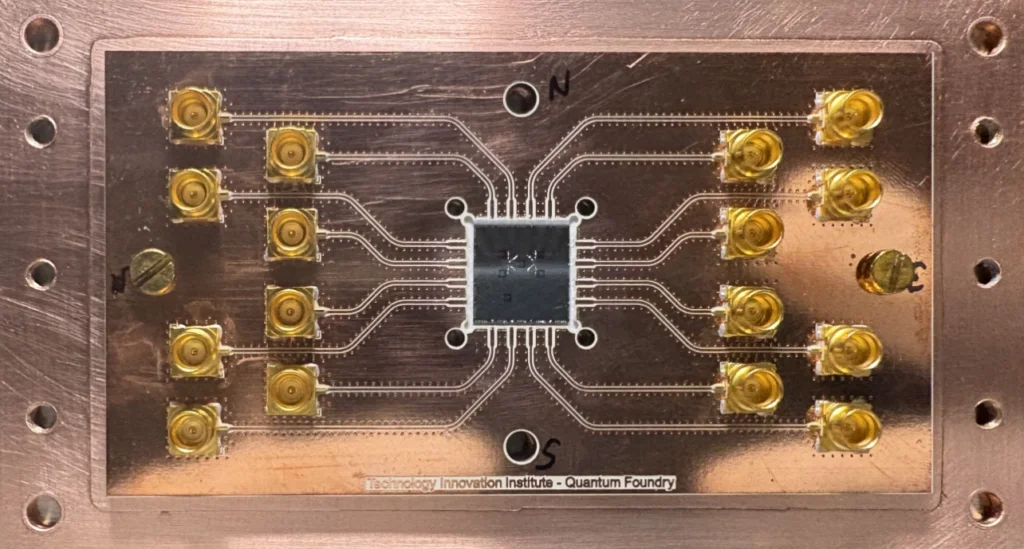

Current machines rely on dense tangles of wires, components and cooling structures that dwarf the tiny chip at the bottom of the machine.

He writes that “The complexity of the plumbing completely overwhelms the quantum device itself.”

Martinis said the solution is to abandon today’s hand-built, research-lab approach and move to fully integrated chips similar to the transformation that turned 1960s mainframes into the microchips inside smartphones. The field, he argued, must invest in cryogenic integrated circuits that can operate at the ultra-low temperatures required for superconducting qubits.

Using that approach, Martinis suggests that engineers could place about 20,000 qubits on a single wafer and reach the million-qubit scale by linking wafers together.

That level of integration would also require abandoning manufacturing methods that date back more than half a century. He singled out the “lift-off” process still used in many quantum labs as too dirty and too limited for industrial-scale production.

The “lift-off” process is an older chip-fabrication technique still used in many quantum research labs. Engineers first coat a wafer with photoresist, expose it to light to create openings, then deposit metal across the entire surface. When the photoresist is dissolved, the unwanted metal “lifts off,” leaving behind the pattern. The method is inexpensive and easy to use, but it leaves residue, produces rough edges and limits how densely features can be packed. Manufacturing experts say those drawbacks make lift-off unsuitable for the kind of clean, highly integrated fabrication needed to scale quantum chips beyond the lab stage.

He also tied the shift to broader economic concerns, writing that offshoring semiconductor fabrication eroded U.S. technological leadership and the stable jobs that came with it. He called for domestic investment so American workers share in the benefits from whatever quantum computing ultimately becomes. “The next great technological revolution must remain tied to the people who build it,” he wrote.

A Shift From Whiteboards to Factories

Martinis said the superconducting-qubit community remains too focused on publishing results and racing toward each new experiment. The field’s culture, shaped by rapid-fire papers and aggressive marketing, favors short-term demonstrations over long-term engineering.

He warned that without a manufacturing overhaul, the field risks leaving quantum computing “forever trapped in a jungle of wires.”

The physics to create a path through this wired jungle, he writes, is largely in place. What’s missing are the engineers and technicians who can turn scientific ideas into scalable machines.

Martinis urged researchers to redirect their efforts. These effort, he added, wouldn’t just help the quantum computing industry — it could create a new industrial revolution that helps bring back manufacturing jobs.

“I grew up in a blue-collar family and I know that manufacturing is the bedrock of good, sustainable jobs in America.” writes Martinis in FT. “When the classical semiconductor industry offshored much of its fabrication capacity, it shifted technological leadership overseas. I do not wish my scientific legacy to simply mint a few more billionaires. We should share the transformative benefits of quantum technology with everyone. The next great technological revolution must remain tied to the people who build it.”