Insider Brief

- QuantLase Research and Development Center in the UAE has completed design and validation of the region’s first industrial-grade photonic chip for AI matrix multiplication, now entering fabrication in Europe.

- The chip performs core AI computations using light instead of electricity, offering potential energy and efficiency gains over traditional electronic processors.

- Built on a silicon photonics platform, the chip passed commercial design checks and export compliance reviews, with delivery, testing, and packaging scheduled through May 2026.

The United Arab Emirates has entered the global chip race with its first industrial-grade photonic computing chip, designed to perform the matrix math at the heart of artificial intelligence. Developed by QuantLase Research and Development Center (QRDC), the chip is now in fabrication at a European foundry and is expected to be delivered by January 2026.

Unlike most early-stage optical computing efforts still stuck in the lab, the UAE chip has passed all design validation milestones and complies with international export control laws. According to the white paper released by QRDC, the chip has been simulated using commercial-grade tools and locked into a real-world manufacturing, testing, and packaging pipeline, marking it as a product milestone rather than a research experiment.

Built for AI, Powered by Light

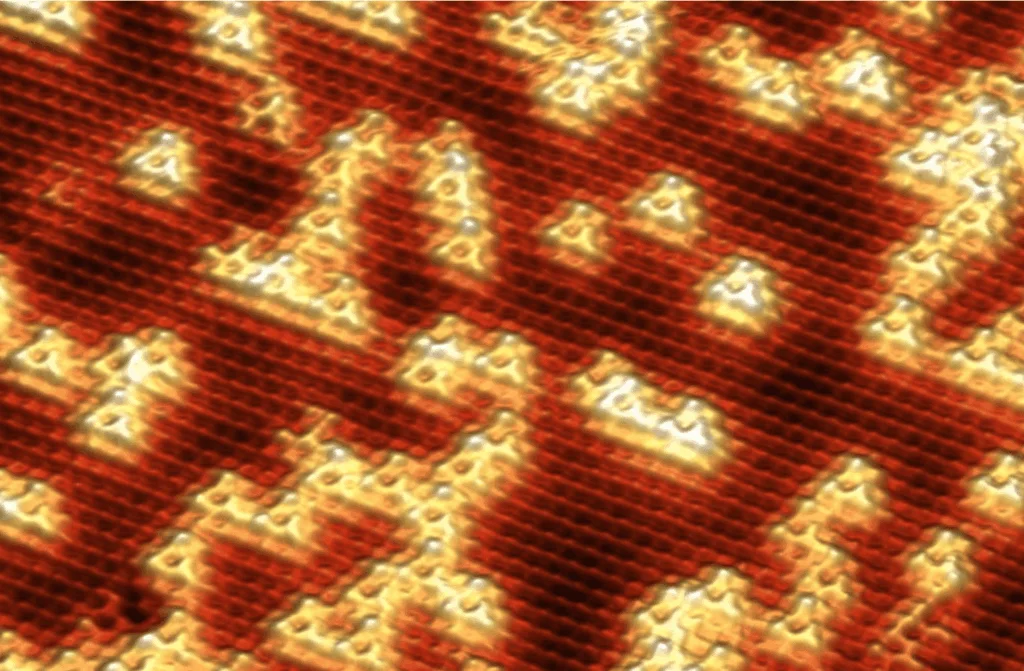

The core function of the chip is to perform matrix multiplication, which is a computationally intensive operation that underpins deep learning algorithms. This work is traditionally done by electronic chips like GPUs, which use electrical signals to process data. The QRDC chip, by contrast, relies on light to perform the same operation using a network of photonic components known as Mach-Zehnder Interferometers. These components split, phase-shift and recombine light beams to execute mathematical transformations, according to the paper.

By shifting this workload from electrons to photons, the chip significantly reduces energy consumption and heat, two growing pain points in data centers. In a country like the UAE, where energy efficiency is a strategic concern, a photonic chip offers not just technical advantage but policy alignment. The QRDC team frames this as part of the country’s broader vision for sustainable AI infrastructure.

Not a Prototype, But a Product in Motion

The white paper emphasizes that this effort is not exploratory science but a tightly engineered hardware rollout. The design has been validated through simulations using Synopsys OptiSim, a standard tool in the photonics industry. All layout files passed foundry-level checks, meaning the chip was confirmed to be manufacturable before a single wafer was produced.

The chip itself is compact — measuring just 5 mm by 10 mm, which is smaller than a postage stamp — and built on a silicon photonics platform, which is compatible with conventional CMOS manufacturing processes. The architecture supports the use of external laser sources, grating couplers for input, and programmable weight matrices for AI inference tasks. This setup mirrors the logic of electronic neural networks, but instead of manipulating electrical voltages, the chip controls light intensity and interference patterns to produce the same effect.

Future versions aim to upgrade the chip from its current thermo-optic tuning mechanism to faster, electro-optic tuning, which would allow real-time reconfiguration suitable for more dynamic AI tasks.

A Strategy of Architectural Ownership

What distinguishes this chip from similar photonic designs, according to the QRDC team, is not its structural novelty but its execution model. The mesh network used in the chip draws from existing photonic architectures, such as the Reck and Clements meshes, which are optical circuit designs that help photonic chips perform complex calculations like matrix multiplication using light, forming a foundation for AI and quantum processing. However, the UAE effort repurposes these components within a system designed from day one for industrial manufacture and regulatory compliance.

This strategy mirrors the fabless business models used by companies like Apple and NVIDIA, which do not fabricate their chips but retain full control over architecture, design and intellectual property. QRDC has followed a similar path as they are developing the chip entirely in the UAE while outsourcing fabrication to Europe. The foundry has also provided integrated testing and packaging services, allowing QRDC to compress its design-to-delivery cycle to under seven months.

Compliance as an Enabler, Not a Constraint

Navigating international export laws was a central challenge, the paper suggests. Photonic chips, depending on their capabilities, can fall under dual-use regulations that restrict their shipment across borders. QRDC conducted a full legal review under the EU’s Dual-Use Regulation and the Wassenaar Arrangement and found that the chip, which does not support encrypted communications or high-frequency military functions, did not require an export license.

This legal clearance allowed the team to integrate European manufacturing pathways without regulatory delays. The white paper frames this as a necessary component of chip sovereignty—arguing that true technological independence lies not in owning factories, but in controlling the architecture and legal pathways that bring a product to market.

A Roadmap Beyond the First Chip

This chip is the first in what QRDC describes as a broader regional roadmap for photonic computing. The current design supports low-speed AI inference but is intended to scale into reconfigurable modules capable of handling real-time workloads. According to the white paper, the organization is already exploring alternative material platforms such as indium phosphide (InP), which could support higher bandwidths and faster control mechanisms.

The design is also modular, meaning it can scale to support larger AI models by adding more layers of interconnected interferometers. Future white papers will reportedly cover ecosystem partnerships, commercial agreements, and use-case pilots.

Although mass production is not yet underway, the white paper presents a detailed timeline: chips will be delivered in January 2026, tested and characterized by March, and packaged into modules by May. These milestones signal a clear progression from simulation to shipping hardware, which could be considered rare for a first-generation chip effort in any country, let alone one without domestic fabrication capabilities.

Limitations and Risks

There is, no doubt, more work to be done. The chip is still in the fabrication phase, and unexpected issues during testing could delay the timeline. Thermo-optic tuning — the current control method — is also inherently slower than the electro-optic methods used in more advanced designs. This limits the chip’s application to inference tasks that do not require real-time adaptability.

The team also acknowledges that long-term reliability, scaling for mass production and integration into larger AI systems remain open challenges. These are typical of early photonic hardware and are not unique to QRDC. Still, the path forward will depend on how well the organization can navigate these hurdles while expanding its ecosystem.

A Regional First, A Global Statement

What makes this development significant is not just the chip itself, but the model it represents, according to the QRDC team. By prioritizing architectural control, legal foresight, and global execution, QRDC has crafted a replicable strategy for hardware innovation in regions without their own fabs.

The effort also dovetails with broader Middle Eastern ambitions to reduce reliance on imported technologies and develop sovereign capabilities in high-impact sectors. While other countries focus on chip fabs and packaging plants, QRDC’s white paper suggests that architecture ownership may offer a more immediate path to influence in the AI hardware race.

For more technical details — that this summary story cannot provide — please review the white paper.