Insider Brief

- China has launched its first production line for thin-film lithium niobate photonic chips, positioning itself to compete in global AI, quantum computing, and 6G markets.

- The CHIPX pilot line achieves performance benchmarks that surpass global standards, including modulation bandwidth over 110 GHz and ultra-low signal loss, while enabling rapid chip iteration.

- Although countries like the U.S. and the Netherlands began earlier, China’s TFLN-based approach and domestic scaling ambitions mark a new phase in the international photonics race.

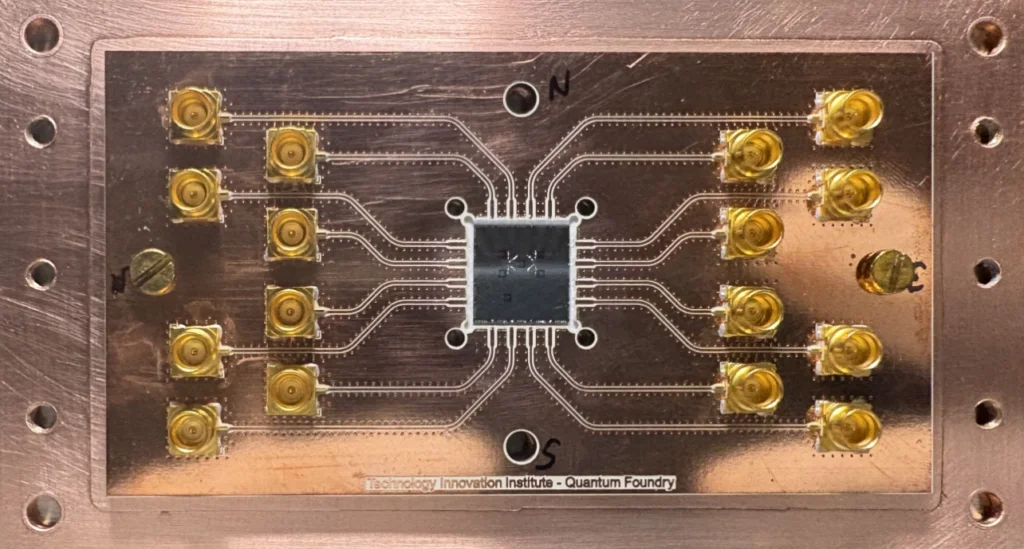

- Image: The new pilot line of China’s TFLN photonic chips has an annual capacity of 12,000 6-inch wafers and features rapid, low-cost production. (SCMP, Handout)

China has launched its first production line for next-generation photonic chips, signaling a leap in its effort to compete in global technology sectors like AI, quantum computing, and 6G networks.

According to the South China Morning Post, the Shanghai Jiao Tong University’s Chip Hub for Integrated Photonics Xplore (CHIPX) announced the completion of a pilot manufacturing line earlier in June capable of producing 6-inch wafers made from thin-film lithium niobate (TFLN), a material increasingly seen as critical to the future of high-performance photonics. The new production facility is China’s first of its kind and delivers technical performance that exceeds global standards in several key benchmarks.

“Establishing this stable production line is the result of nearly 15 years of effort,” said Professor Jin Xianmin, director of CHIPX, as reported in SCMP. “I began working on photonic chips in 2010 and focused on lithium niobate from 2018,” Jin said. “Before this pilot production line, we spent years refining fabrication techniques, building small-scale prototypes, and solving critical issues. For instance, achieving efficient coupling between electrodes and the optical chip required a long and technically demanding process from design to tape-out to testing.”

Unlike traditional semiconductor chips that rely on electrical signals to process information, photonic chips, as their name suggests, use light. This makes them faster, more efficient, and less power-hungry — traits that are particularly valuable for the high data demands of AI model training, large-scale cloud computing, and quantum communication. But manufacturing them has proven challenging due to the delicate nature of the materials involved.

Prize Properties, Limited Production

TFLN is prized for its ultra-fast electro-optic properties, offering high bandwidth and low power consumption. Its brittle structure, however, has historically limited its use in large-scale manufacturing. The CHIPX pilot line overcomes that limitation with a fully integrated production chain that includes more than 110 advanced fabrication tools. The researchers behind the project report the facility’s goal is full technological self-reliance — to handle every step from lithography and etching to final chip packaging.

“To ensure stability and reduce uncertainties in both materials science and fabrication techniques, the production line currently uses top-tier international equipment,” Jin told the SCMP. “In the future, we have the ability to gradually adopt domestic or refurbished alternatives, with some Chinese teams already able to provide third-party maintenance for the current machinery.”

This progress follows three years of construction, which began in 2022. Process engineers working on the line refined techniques such as annealing, which is a heat treatment method used to repair surface defects, allowing the team to meet strict requirements for photonic chip fabrication. Smooth surfaces are essential for minimizing energy loss when guiding light through tiny circuits, SCMP reports.

CHIPX scientists said that the chips now exceed a modulation bandwidth of 110 gigahertz, a threshold long considered a global performance barrier for high-speed optical communications. In addition, signal losses—key metrics for chip quality—have been significantly reduced. Insertion loss has dropped below 3.5 decibels and waveguide loss is under 0.2 decibels per centimeter. These improvements suggest the chips are capable of supporting advanced optical links with much greater efficiency than previous designs.

Production Just Getting Started

While China’s photonic chip production is just getting started, other countries have already built capacity. In the Netherlands, SMART Photonics began producing 4-inch indium phosphide wafers last year. California-based PsiQuantum, which is developing a fault-tolerant quantum computer based on photonics, is working with GlobalFoundries to adapt an existing 300-millimeter silicon photonics line, SCMP reports. These companies are also targeting AI and quantum sectors, but the use of TFLN provides the Chinese facility with a different technical path and potential performance advantages.

CHIPX researchers have framed the pilot line as part of a broader vision: a shift toward computing architectures that use light not just for transmitting data, but for doing the calculations themselves. Photonic computing promises inherently parallel processing with low latency and energy use—attractive features for training AI models, managing 6G network loads, or eventually running quantum algorithms.

“These lithium niobate photonic chips can function not only as computing servers themselves but also as critical components for photonic-electronic integration,” Jin said, according to SCMP. “They enable the high-speed connection of various computing resources.”

The pilot line is already positioned for scale, with an annual capacity of 12,000 6-inch wafers. That positions the facility to quickly supply commercial customers if demand accelerates.

“Previously, it could take up to a year to fabricate and test a single quantum photonic chip,” Jin said. “Now, we are iterating weekly. This speed is critical for advancing quantum photonic technologies.”

According to the team, this includes future applications in supercomputing, cloud data centers and mobile infrastructure. Photonic chips have obvious dual use capabilities for defense.

“Beyond computing and connectivity, photonic chips also hold promise for applications such as laser gyroscopes, lidar, and biosensing,” Jin added. “The field has seen steady research progress over the years, but what it has lacked was a scalable production path.”

China’s broader photonics industry is also gaining traction, according to SCMP. Hangzhou-based Xili Photonics, another player in the sector, recently secured major investment. CHIPX itself was named a priority platform under a national initiative by the Ministry of Industry and Information Technology, marking it as a key part of China’s strategy to close the gap with global leaders in chip production.

“Our platform is currently a national pioneer,” Jin said. “This production line can develop prototypes into small-batch production for scientists, research institutes and companies, while also accelerating the validation of cutting-edge technologies – from zero to one.”

The goal is to further stabilise its production process, increase yields, experiment with other materials and eventually scale to 8-inch wafer fabrication, according to CHIPX.