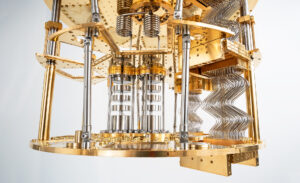

Cryogenic environments are vital to quantum technology and the Bluefors team.

Helsinki-based Bluefors, specializes in cryogen-free dilution refrigerator measurement systems on behalf of the quantum computing and information community and sees cryogenics as a worthwhile opportunity.

“From our point of view, cryogenics is not an obstacle to taking the quantum technology forward, but an opportunity to explore the quantum realm for microelectronics circuits,” said Dr. David Gunnarsson, Chief Sales Officer and principal scientist at Bluefors.

“The quantum bits — or qubits — in a quantum computer operate on the fundamental level of nature, which means there are no room for errors and every interaction between the qubits environment counts,” said Gunnarsson, explaining why the very nature of quantum exploration makes cryogenic expertise necessary.

“For a quantum computation, a single unwanted photon is enough to disrupt the function of the qubit. Therefore, control of the environment is fundamental.”

Gunnarsson explained how this is a vastly different environment from classical computing or logic where the zeros and ones are backed up with margins that allow a computer to function even if there is noise from environment. “For a quantum computation, a single unwanted photon is enough to disrupt the function of the qubit. Therefore, control of the environment is fundamental.”

However, trying to control this environment raises several challenges. The fabrication of the qubits requires well-chosen steps and processes to avoid unwanted degrees of freedom in the device’s physical environment. A further challenge is establishing full control of the qubits while making sure no unwanted signals change their state. This demonstrates the importance of the cryogenic measurement system, added Gunnarsson.

“The need of cryogenics in quantum computation comes from the fact that many qubit schemes today operate on an energy level that corresponds to signals at GHz frequency,” said Gunnarsson. “The advantage here is that a lot of microwave technology exists commercially for control of the qubits and it is possible to operate at a high clock speeds of computation.“

“To be able to control quantum states at energy levels corresponding to GHz frequencies, the temperature of the qubits must be well below 100 mK. In addition to having the qubit devices at ultra-low temperatures, all connections for the control of the qubits must be well filtered and shielded to avoid any stray signals interfering with the qubit” Gunnarsson continues.

“This is where cryogenics comes in and especially a cryogenic measurement system that can keep the qubits and the measurement infrastructure at temperatures where their quantum nature can be harvested,” explained Gunnarsson.

Just keeping a qubit relatively safe from noise is difficult enough, but the team at Bluefors recognize this is as one of the challenges quantum engineers face.

Just keeping a qubit relatively safe from noise is difficult enough, but the team at Bluefors recognize this is as one of the challenges quantum engineers face.

As the number of qubits scale up to a number large enough to perform practical computations, all the above challenges remain present, while growing in complexity.

“When it comes to cryogenics, it is a mature technology and solutions exist for scaling quantum computers to numbers well above 1000 qubits –that is with limitations in the current way of doing quantum computation at ultra-low temperatures,” said Gunnarsson. “In this sense, scaling is more of an engineering effort, as well as making the right choices.”

“Cryogenics has matured in the last 20 years and today one can reach millikelvin temperatures with basic lab infrastructures, at a push of a button, and systems can continuously run for at least a year.”

Cryogenics is Improving to Meet the Challenge

Cryogenics has long held a reputation of being unreliable, difficult, and high maintenance and a major factor in this may be because of the difficulty of operating at cryogenic temperatures, compared to room temperatures.

As things are changing, Bluefors researchers are playing a key role in supporting the improvements to cryogenics to meet the needs of its customers.

“Cryogenics has matured in the last 20 years and today one can reach millikelvin temperatures with basic lab infrastructures, at a push of a button, and systems can continuously run for at least a year,” said Gunnarsson. “The investigations into quantum technology have also improved the cryogenic measurement infrastructure and it is now possible to get systems commercially ready with all the measurement infrastructure you need to make a quantum measurement. As recent app notes show.”

The Bluefors Reputation

Bluefors advantages help them stand out amongst a handful of companies that can deliver cryogenic systems for devices operating at temperatures below 10 mK.

It has established a solid reputation for utilizing scientific equipment and building reliable systems with scalable production. This has allowed Bluefors to lead the way in quality and performance, and ensured the company’s products and services are the preferred choice for applications requiring long term reliability.

Explaining Bluefors unmatched reputation in the quantum field, Gunnarsson says “Bluefors has a strong focus towards quantum technology, with systems for both academic research and direct quantum computation applications. The systems today are cryogenic measurement systems, ready for the application they will support. Here Bluefors has worked together with the research community to adopt the correct requirements and create a measurement system that works out of the box.”

Cryogenics Helps Quantum, Quantum Helps Cryogenics

The emergence of ever improving quantum technology is heavily influencing the cryogenic market and available technology and challenging manufacturers to meet the changing requirements. The advances have allowed it to be a basis for other technologies, where low temperatures are required. Widening the scope for use has made cryotechnology more necessary and, therefore, standard in many labs today.

“We see that the basic research and development that requires cryogenics will grow due to this and envision having a cryogenic measurement system in your lab will be, figuratively speaking, as normal as having an oscilloscope there,” said Gunnarsson.

Bluefors utilizes this symbiotic relationship between emerging quantum technology and cryogenic innovation, invests heavily in the development of its products to keep in line with industry development and meet the ever-changing needs of their customers.

“We have also formed partnerships to be ready for the requirements we see in cryogenics in the future,” said Gunnarsson. “A good example of this is our collaboration with Linde and Afore, both companies with complementary technologies to the cryogenics from Bluefors. These partnerships allow for cryogenic measurement systems that supports the growth for technologies that require cryogenics.”

The company has also developed a service network to offer customers an even more convenience.

Service from Inquiry to Delivery and Beyond

Gunnarsson describes Bluefors commitment to excellent customer service from initial inquiries to final delivery and ongoing support.

Systems are tested before leaving before leaving the factory and once on site, Bluefors specialist engineers provides expert installation and commissioning. Thorough training is provided for the customer on the operation of the system, while ensuring the system operates to set specifications.

“Bluefors have a strong product portfolio and the customers always get the highest quality products, which are factory tested to ensure function. Once installed, the customer has direct access to support engineers” said Gunnarsson. “Bluefors has an established service program and customers can add safety to their operation with different service options.”

Learn more about Bluefors at their website.

If you found this article to be informative, you can explore more current quantum news here, exclusives, interviews, and podcasts.