With waste pollution piling up around the globe, many scientists are trying to find new ways to minimize waste products. From recycled materials to biodegrade plastics, these materials can be repurposed or easily broken down. Other researchers are looking at entirely new uses for waste products. It may sound stranger than fiction, but the fields of nanotechnology and quantum technology could find a new influx of resources from, of all places, microbreweries. In a new study published in RSC Advances, scientists from the Institut national de la recherche Scientifique (INRS) believe they can create quantum dots with beer product waste.

The Applications of Quantum Dots

As a type of nanotechnology, quantum dots have a wide range of applications. These man-made nano-crystals are designed to help transport electrons. The crystals are semiconductors, and when electrons hit the crystal, they emit different colors of light. With this versatility in output, these dots can be used in solar cells, light displays, imaging systems, and more. These dots can also have different properties depending on how they’re designed. Their variation in shape, structure, and composite materials can easily affect their output. This makes quantum dot technology attractive for use in photonics, electronics, sensing, and even medicine. To create reliable dots that vary in these characteristics, the manufacturing plant needs to be able to produce large quantities of identical crystals made of the same materials. For this to happen, the same resources need to be used, which is where the breweries come in.

Current quantum dots are often produced with heavy metals that are toxic, such as cadmium. To make these products sustainable and less harmful, researchers are looking at carbon as a potential source material for its accessibility and biocompatibility. Researchers at INRS connected carbon quantum dots to organic brewery waste when looking at the composition of the waste. According to Professor Federico Rosei of INRS: “The use of spent grain highlights both an eco-responsible approach to waste management and an alternative raw material for the synthesis of carbon quantum dots, from a circular economy perspective.” The brewery waste was not only high in carbon but also in nitrogen and phosphorus, avoiding the need for purified chemicals. This would allow the manufacturing process to go faster and be more cost-effective.

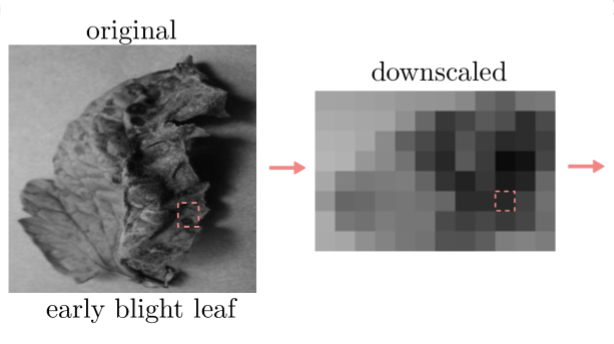

To test their proposed methods, the researchers collaborated with a team at the École de technologie supérieure (ÉTS). They first used a normal microwave to carbonize the grain products, reducing the products to dark powder. The powder was mixed with purified water and re-microwaved. From there, the mixture was filtered heavily to produce a prototype quantum dot. The finished product could identify and measure the concentration of heavy metals and other contaminants that impact water quality, something that current quantum dots can also do. Obviously, more research needs to be done to create a more efficient product, but the team is hopeful that their method could be utilized elsewhere.

For the researchers, this experiment was far from normal. “This research was a lot of fun, lighting up what we can do with the beer by-products,” explained the Canada Research Chair in Sustainable Multifunctional Constructional Materials at ÉTS, Claudiane Ouellet-Plamondon. “Moreover, ÉTS is located on the site of the former Dow brewery, one of the main breweries in Quebec until the 1960s. So there is a historical and heritage link to this work.” The switch from cadmium to carbon quantum dots will clearly not happen overnight, but it does suggest ways that the industry can be more environmentally conscious while cutting costs.

For more market insights, check out our latest quantum computing news here.